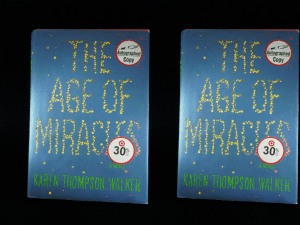

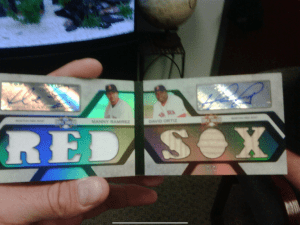

In the printing industry we do different many things, including machining for retail products, such intricate Topps’ trading cards to machining book jacket covers, such as for Age of Miracles.

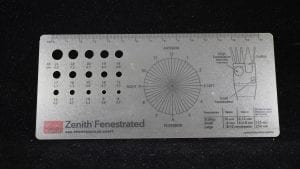

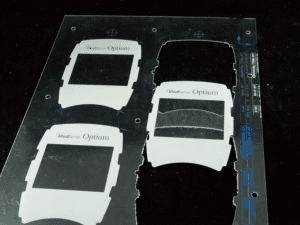

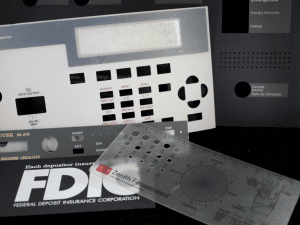

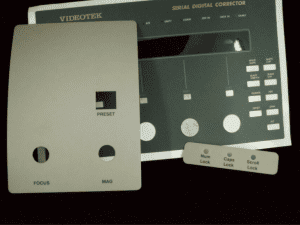

In the commercial space, we machine print materials on a regular basis. It used to be that people would screen print thin materials, such as Mylar, then make a rigid stiffener to support it. We’ve been able to combine the process; we have the rigid stiffener printed directly on the material and then machine it. We can also have it reverse printed, so that when installed, it’s printed on the inside and seen from the front, thus protecting the screen printing by not allowing it to scratch off.

We can also use UV-coated and protected materials to keep the color vibrant for outside conditions. These are used in machine guards, face plates, and more, and usually have the customer logo included.

These can come with full- or zoned-adhesive for self-adhering, drilled holes for mounting, and all our regular- and post-matching can be done to printed parts as well.