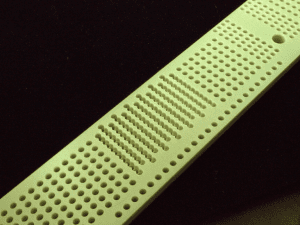

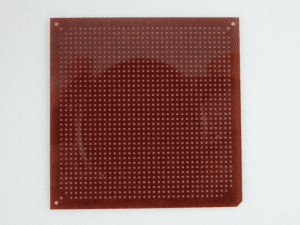

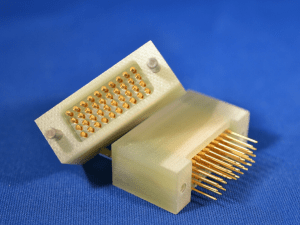

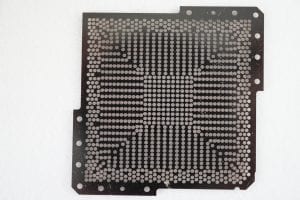

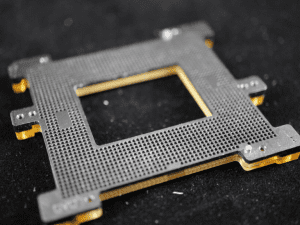

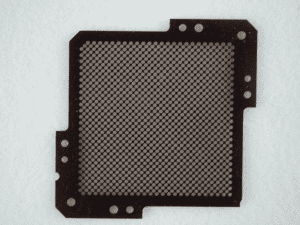

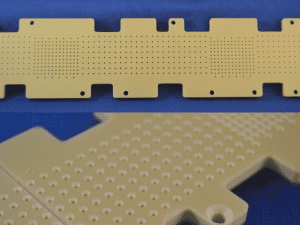

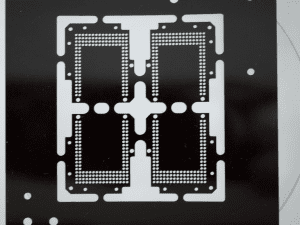

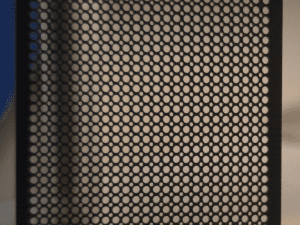

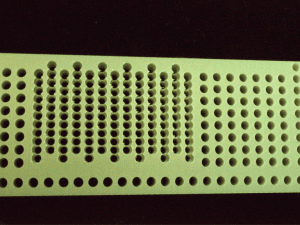

At QC Precision Machining, we specialize in the precision machining of electronic components, including Pin Grid Arrays (PGA) and Ball Grid Arrays (BGA), which are critical for making reliable connections between circuit boards. Our expertise in this area is unmatched, offering significant advantages over traditional die stamping methods, especially when small tolerances are required.

Innovative Stacking Techniques from QC

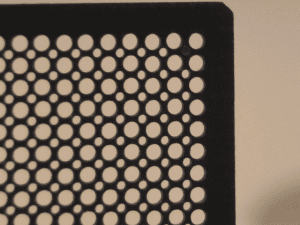

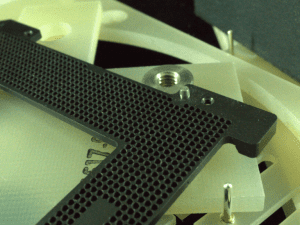

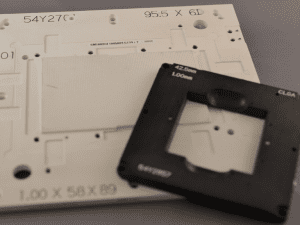

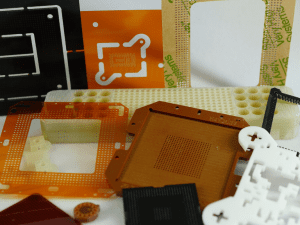

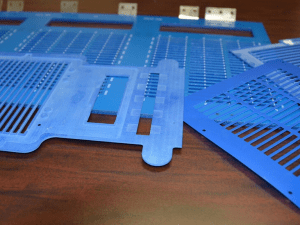

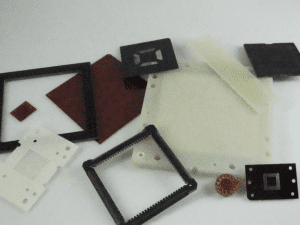

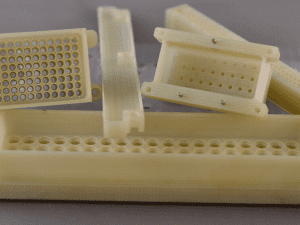

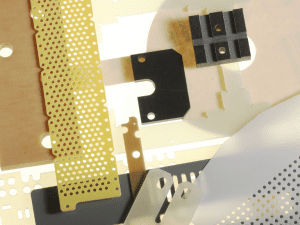

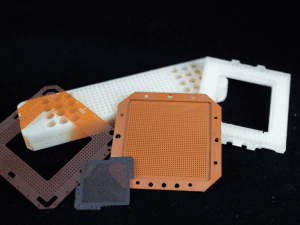

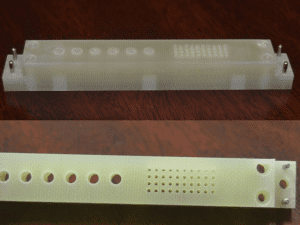

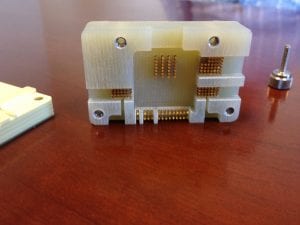

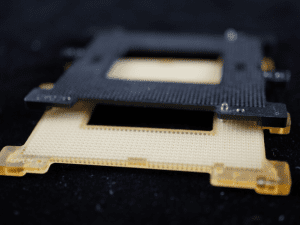

Our advanced stacking techniques play a crucial role in the production of PGAs and BGAs. By stacking materials, we can efficiently produce hundreds of pieces for testing, ensuring consistent quality across each component. This method allows us to maintain tight tolerances, which are essential for the reliable performance of electronic components. Unlike die stamping, where tooling costs range from $65K to $75K and revisions are nearly impossible, our machining process offers flexibility and precision at a lower cost, making it ideal for both prototyping and production.

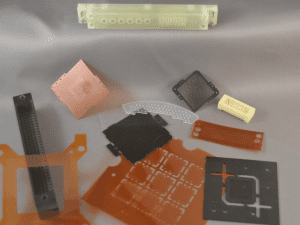

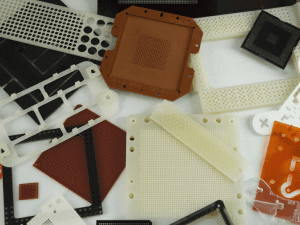

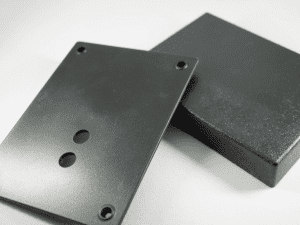

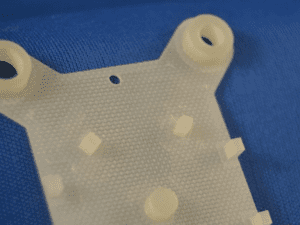

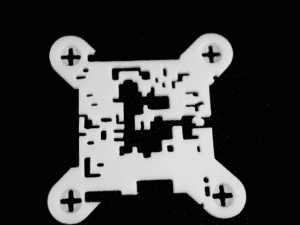

We machine a variety of parts in multiple materials, including the highly popular PGA and BGA wafer modules, Interposer dies, Chip nests, Sockets, Test sockets, Carriers, Board-to-Board modules, Stiffeners, Spacers, Washer inductor core, Header boards in Kapton, FR-4, Cirlex, Ultem, Mylar, and many more.

QC Quality You Can Trust

When it comes to electronic components, precision is everything. Our machining process delivers superior quality, particularly for small tolerances where die stamping falls short. We understand that these components are often the final step in a complex assembly process, so we ensure that every piece meets the highest standards of quality and reliability.

QC’s Proven Success

Our track record speaks for itself. We’ve successfully partnered with companies to provide a wide range of precision-machined components with numerous moving parts. Whether you need parts for connecting elements within a design or intricate components for electronics, we have the capabilities and experience to meet your needs.

Why Choose QC Precision Machining?

- Expertise: With decades of experience, our team is equipped to handle even the most challenging projects.

- Flexibility: Our machining process allows for revisions and adjustments that are not possible with die stamping.

- Quality: We deliver consistent, high-quality results that meet the stringent demands of the electronics industry.

- Partner with QC Precision Machining for your next project and experience the difference that precision machining can make.

Contact us today to learn more about our services and how we can help bring your designs to life.