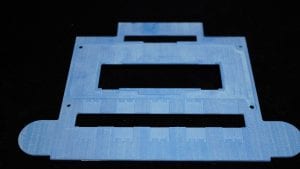

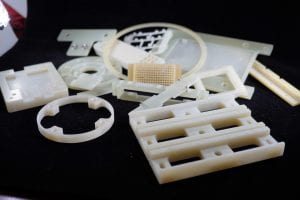

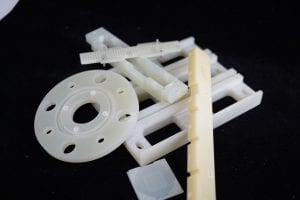

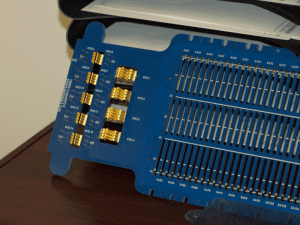

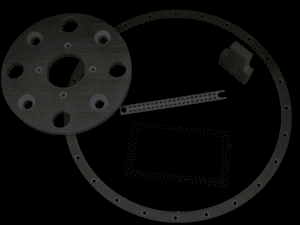

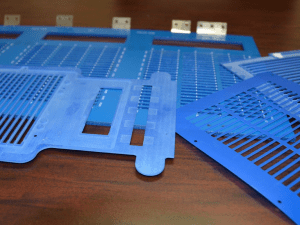

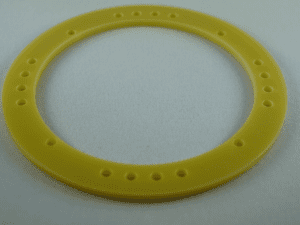

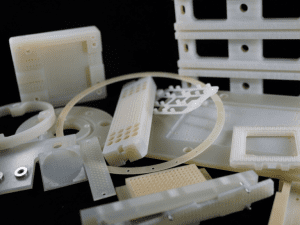

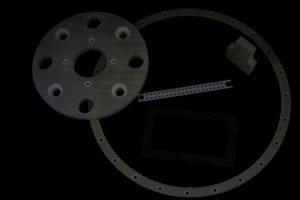

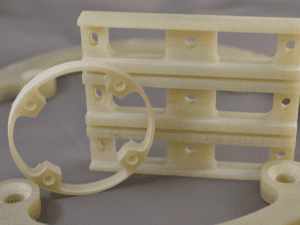

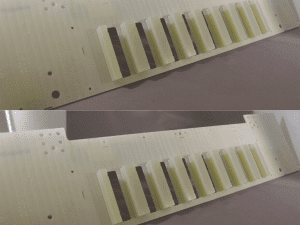

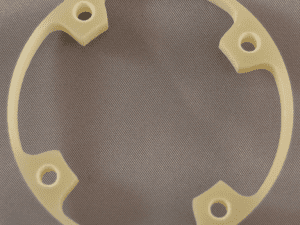

We have made lots of parts for suppliers to the Department of Defense. We’ve machined Stiffeners, Shields, Spacers, Shims, Gaskets, Face Plates, Back planes, and other products out of many materials, such as ABS, Delrin, FR-4, G-10, Mylar, Nylon, Polypropylene, UHMW, and Ultem.

Our parts have ended up in military planes, missiles, and boats, as well as somewhere on the ISS (International Space Station), and some other classified projects.

From rapid prototyping to full-scale production, we deliver quality, efficiency, and innovation in every project.

Truly Made In America

We source all our materials from trusted American suppliers, ensuring that every part we produce meets the highest standards of quality and compliance. Our advanced capabilities, including specialized stacking techniques and the use of multiple heads, set us apart from competitors by allowing us to deliver precision and efficiency in every project.

Our Collaborative Approach

We believe that collaboration is key to successful project outcomes. Our team works closely with clients from the initial design phase through to the final prototype, offering full consulting services to make parts more manufacturable and cost-effective. This collaborative approach ensures that our clients receive customized solutions that meet their specific needs and exceed their expectations.

With QC Precision Machining, you’re not just getting a service provider—you’re gaining a partner committed to your success.