At QC Precision Machining, we offer unparalleled flexibility for contract manufacturers, seamlessly aligning our diverse machining capabilities with the varied requirements of your products. Whether you’re producing intricate components or robust assemblies, our facility is equipped to handle multiple builds across different projects simultaneously.

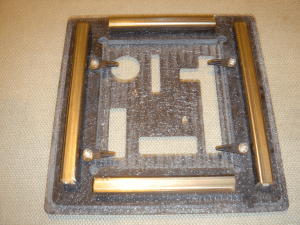

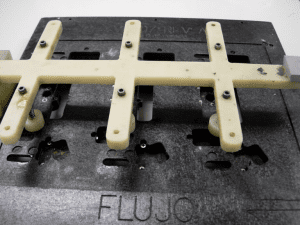

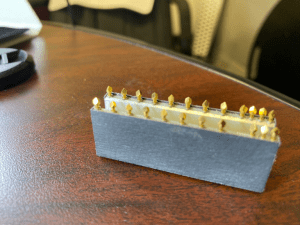

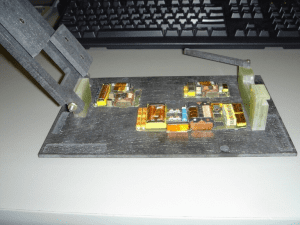

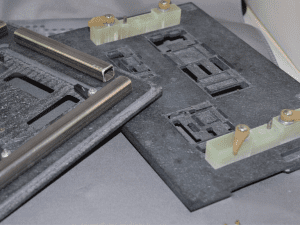

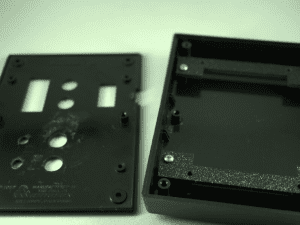

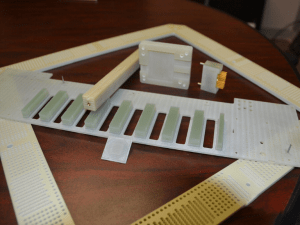

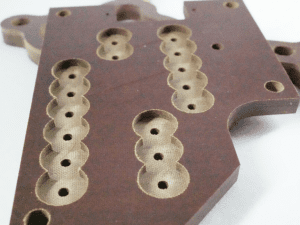

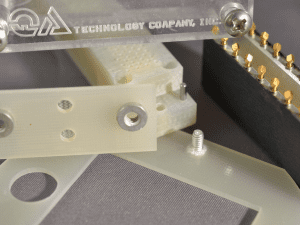

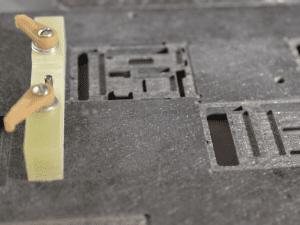

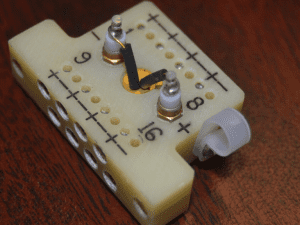

For example, we can precision-machine a delicate .005″ Kapton PGA module on one machine, while simultaneously milling a 1/2″ thick FR-4 component on another. This capability allows us to efficiently manage multiple products for the same or different contract manufacturers at the same time, ensuring that all your production needs are met without delay.

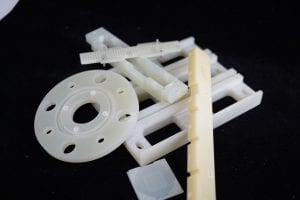

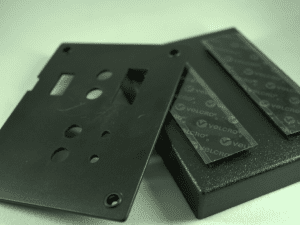

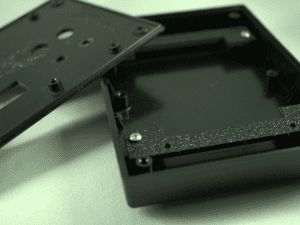

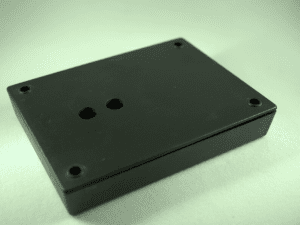

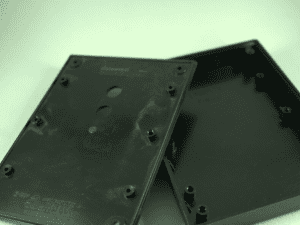

Our expertise in working with a wide range of materials and thicknesses—from .001″ Kapton to 1″ FR-4, Lexan, Delrin, Nylon, Acrylic, and more—enables us to produce thousands of variations of parts. This versatility ensures that we can meet the specific requirements of your projects, no matter how complex or varied they may be.

Partner with QC Precision Machining to experience the benefits of a flexible, responsive, and reliable contract manufacturing partner. Let us help you bring your products to market with precision and efficiency.