Electrophoresis Combs

We deliver fast turnaround, custom electrophoresis combs and spacers, as well as other components for the biomedical industry.

Electrophoresis combs are critical components in laboratory procedures for DNA, RNA, and Protein cell research. These combs create wells in gels used for electrophoresis, a technique that separates molecules based on size and charge. The accuracy and precision of these combs directly impact the consistency and reliability of experimental results.

QC Precision Machining is able to deliver custom combs of any material without requiring much information from the customer.

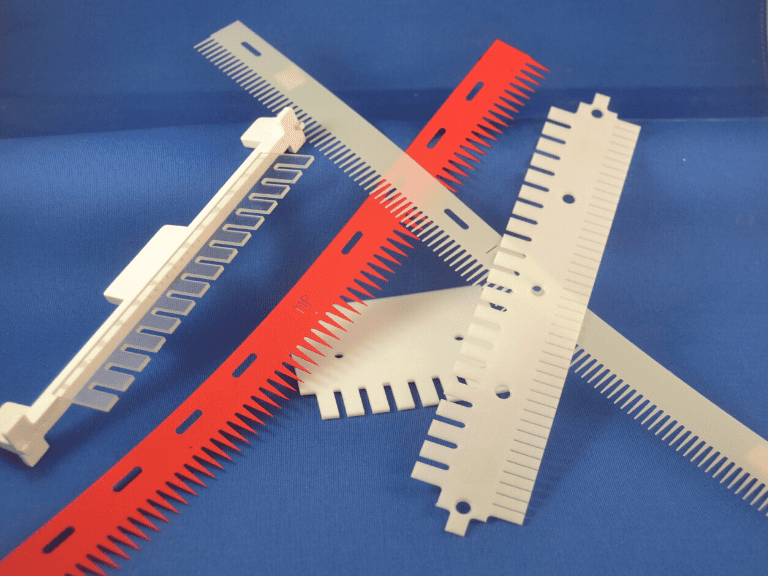

Check out our work:

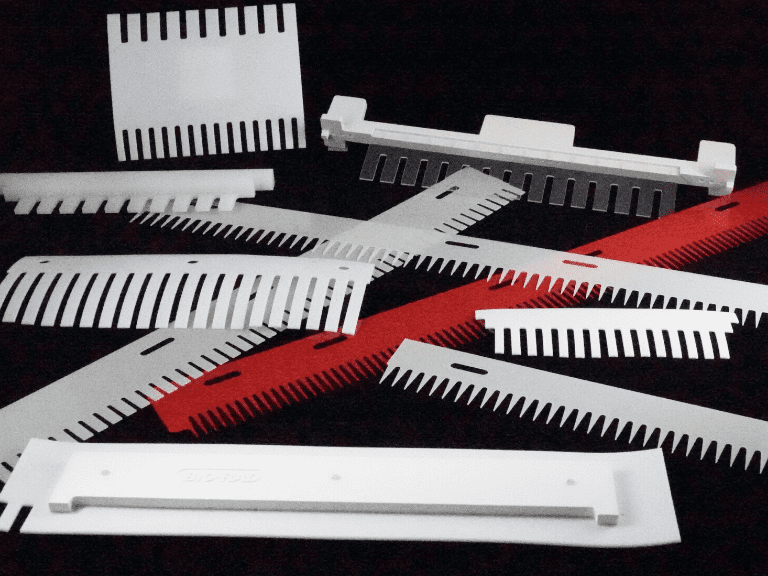

- The first image below shows a variety of combs we’ve made.

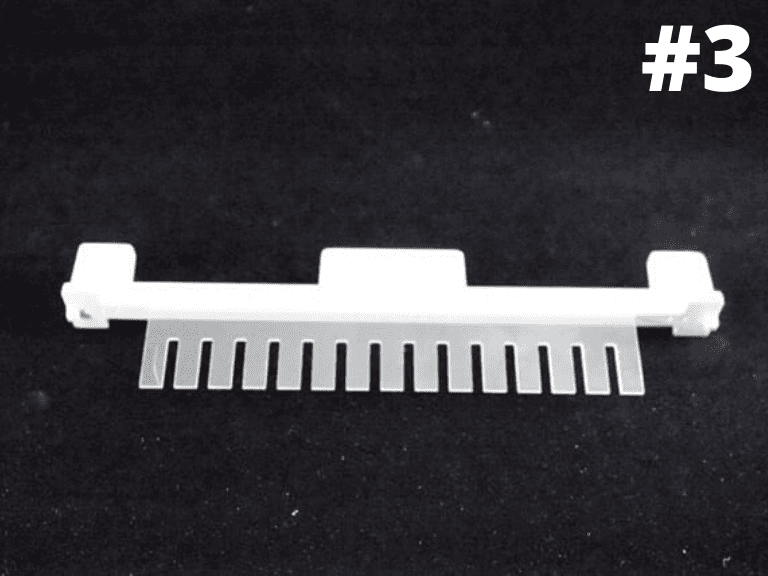

- Pictures 2 and 3: we machine the comb then ultrasonically weld our comb to an injection-molded spacer.

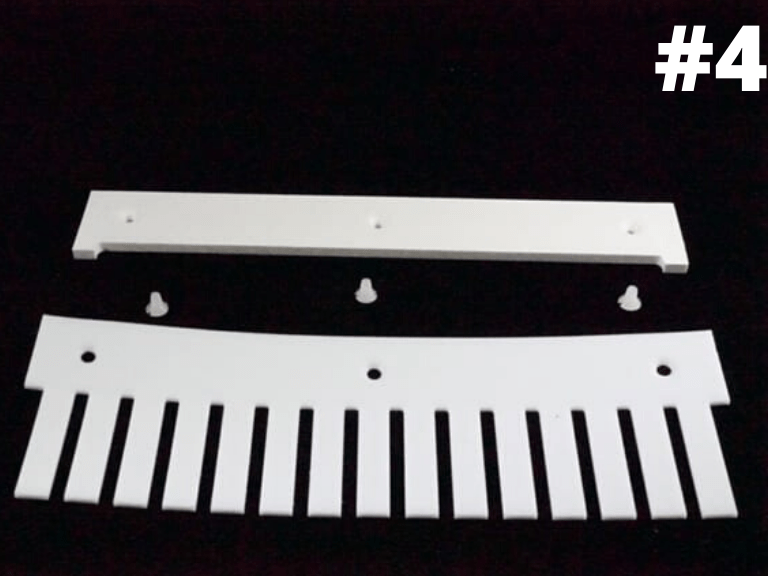

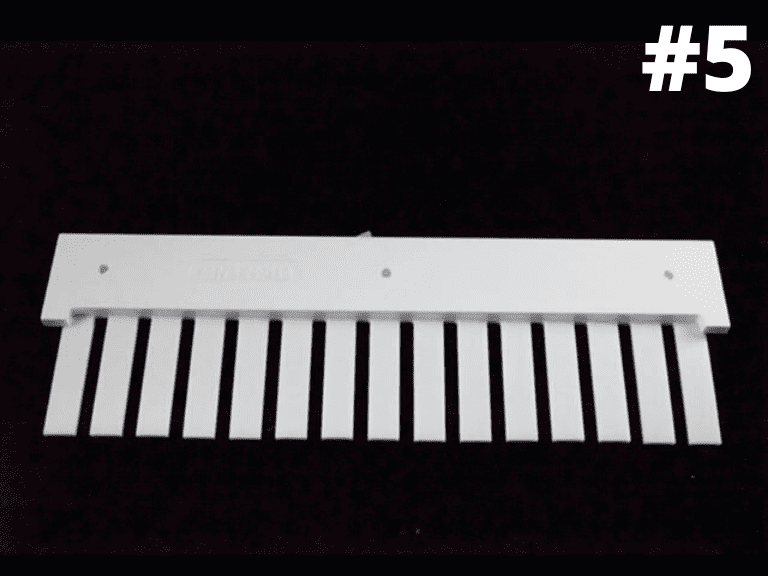

- Pictures 4 and 5: we machine a comb and assemble to injection molded spacer with screws.

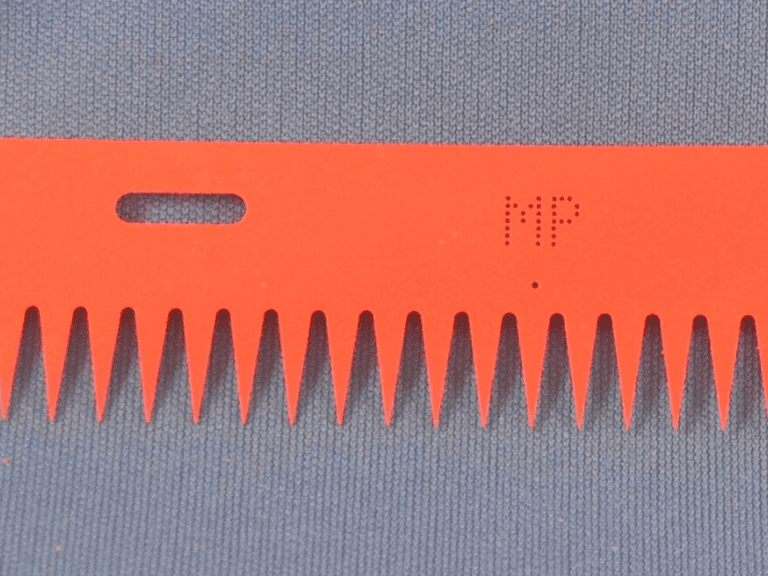

The production of electrophoresis combs demands high precision and uniformity. The combs must have well-defined teeth with consistent spacing and dimensions to ensure accurate sample loading and separation. Our plastic sheet and film machining process meets these stringent requirements, making it the preferred method for manufacturing electrophoresis combs.

We can turn your quote around in one day.

Shoot us a message to get the process started.

Why Choose QC Precision Machining?

Precision and Accuracy

The precision and accuracy of our plastic sheet and film machining process are paramount in the production of electrophoresis combs. Our unique process allows for the creation of combs with exact dimensions and tolerances, ensuring consistent well sizes and spacing. This level of precision is crucial for reproducible experimental results in protein analysis and DNA research (Vu et al., 2018).

Customization

Customization is another significant advantage of plastic sheet and film machining. Researchers often require combs tailored to specific experimental setups. The flexibility of sheet and film machining allows for the quick and cost-effective production of custom combs, enabling researchers to meet their unique requirements without significant delays.

Durability and Performance

Electrophoresis combs manufactured through plastic sheet and film machining exhibit excellent durability and performance. The use of high-quality materials and precise machining techniques ensures that the combs can withstand the rigors of repeated use in laboratory settings. This durability translates to longer-lasting tools and reduced costs for research laboratories (Vu et al., 2018).

We can turn your quote around in one day.

Shoot us a message to get the process started.

Future Prospects of Plastic Sheet and Film Machining

The future of plastic sheet and film machining is promising, with several technological advancements and trends poised to shape the industry.

Advanced Materials

The development of new materials with enhanced properties will expand the capabilities of plastic sheet and film machining. Researchers are exploring biocompatible and biodegradable plastics that offer improved performance and sustainability. These materials will enable the production of advanced biomedical tools that are both effective and environmentally friendly (Vu et al., 2018).

Automation and AI Integration

The integration of automation and artificial intelligence (AI) in machining processes will enhance precision and efficiency. Automated systems can optimize cutting paths and parameters, reducing human error and increasing productivity. AI-driven predictive maintenance can also minimize downtime and extend the lifespan of machining equipment (Yang et al., 2018).

Hybrid Manufacturing Techniques

Hybrid manufacturing techniques that combine plastic sheet and film machining with other methods, such as 3D printing and additive manufacturing, will offer new possibilities for creating complex and highly customized biomedical tools. These hybrid approaches can leverage the strengths of each technique to produce parts with intricate geometries and superior performance (Aksenov & Kononov, 2020).

Expanded Applications

As technology advances, the applications of plastic sheet and film machining in biomedical research will continue to grow. Potential future applications include:

- Personalized Medicine: Customized biomedical tools and devices tailored to individual patients will become more feasible. This could include patient-specific surgical guides, implants, and diagnostic tools (Yang et al., 2018).

- Regenerative Medicine: The precision and versatility of plastic sheet and film machining will support the development of scaffolds and other structures used in tissue engineering and regenerative medicine (Vu et al., 2018).

Sustainability and Environmental Impact

The focus on sustainability will drive innovations in plastic sheet and film machining. Future advancements will likely include:

- Recyclable Materials: The development of recyclable and biodegradable plastics will reduce the environmental impact of biomedical tools and devices. This aligns with the growing emphasis on sustainability in manufacturing (Yang et al., 2018).

- Energy Efficiency: Advances in machining technology will also focus on reducing energy consumption, making the production process more eco-friendly (Yang et al., 2018).