Four Decades of Exceptional Service

Since starting 40 years ago as QC Drilling, QC Precision Machining remains focused on providing quality plastic components to customers and regional manufacturers around the globe quickly and cost effectively.

We are creative custom plastics manufacturing innovators who can help you complete your project, with quality precision, faster than any other company in the machinery and equipment (M&E) industry.

QC Precision Machining can make remarkable improvements in your product design, quality, and time to market because fabricating precise custom plastic components – with the highest quality and tightest tolerances as efficiently and cost effectively as possible – is our passion.

We have completed projects of every size and scope, from quick-turn drilling of plastics used in biomedical parts, to precision fabrications that make Topps’ Company trading cards more unique and valuable.

Some of our products, and what they are a part of include:

- SONAR LOCATORS

- Used to find JFK Jr’s plane

- Used to search the Tigris River in Iraq

- MACHINED PARTS

- Launch mechanism for the Patriot missile

- F-117 stealth fighter planes

- Hubble Space Telescope

- International Space Station

- MACHINED COMPOSITE TILE

- NYC Transit Authority

- MACHINED TRADING CARDS

- The Topps’ relic triple-thread series

- DNA ELECTROPHORESIS COMBS

- For mapping the human genome

- MACHINED ASSEMBLY RING

- Lockheed Martin’s bomb detection machine used at airports

- COIL HOLDER

- MK50 advanced lightweight torpedo

- MACHINED SHEET SEPTUM

- Rolls Royce aircraft engines

- MACHINED FILM OPTICS SPACER

- Veinsite vein imaging

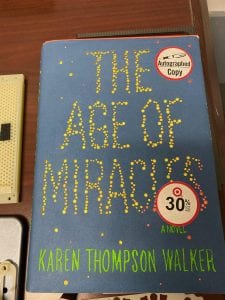

- MACHINED BOOK COVER

- The Age of Miracles. We drilled holes in 60,000+ books.

We’re a trusted partner to product engineers at global companies such as Abbott Labs, Amphenol, Bio Rad, IBM, L3, MIT Lincoln Labs, Phillips Medical, Plexus, TE Electronics, Teradyne, Thermal Fisher Scientific, and Virginia Panel. We have earned a reputation for innovation, speed, and precision fabrication of crucial plastic components.

Equipped with expert production teams, proprietary CAD tools, and state-of-the-art technology for plastic milling, counter-boring, and micro machining, QC Precision Machining regularly completes jobs faster than most shops can even consider.

We utilize technology as much as possible; including being a paperless machine floor Since 2004.

No other facility for plastic machined parts does as much, as fast, as well as, or with the highest quality control or the tightest tolerances as QC Precision Machining.